PHARMACEUTICAL FACILITIES

MODULAR CLEANROOMS

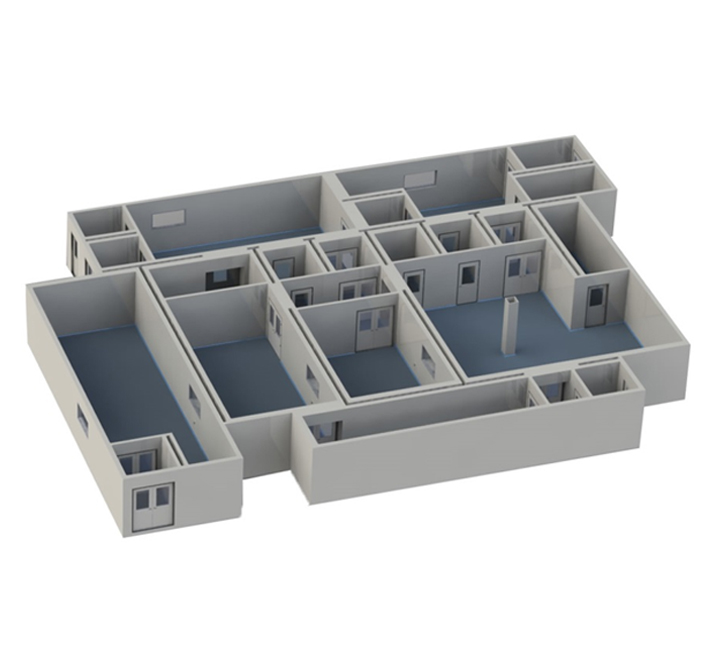

UNIFORM CONSTRUCTION The wall and ceiling systems are pre-fabricated in a shop environment by skilled crews that are 100% dedicated to the task of building pharmaceutical grade cleanrooms under monitored conditions, avoiding the dust and trash found at every job site with stick-built structures. Our modular cleanroom systems are assembled on-site with virtually no excess debris, keeping the work space exceptionally clean, and ensuring a faster start-up of your new facility.

MORE USEABLE FLOOR SPACE Modular walls are just 1.75” thick. Standard wall systems typically start at 4.5”/5.5” with double drywall. A surprising amount of valuable floor space can be lost due to thick walls. Modular is a better option.

CLEAN FAST TRACK CONSTRUCTION

Fabrication start-ups upon drawing approval with typical completion in 11—18 weeks depending upon complexity, size and design of project.

DURABILITY

Our phenolic wall systems are extremely durable and constructed with strong, self-supporting aluminum framework; they are tested against prolonged exposure to most chemicals and all of those commonly used in pharmaceutical cleanrooms for cleaning and sanitation. In addition, our wall systems are resistant to bumps, scrapes and dings eliminating the need of costly repairs. We offer five standard colors, or a variety of premium colors are available, eliminating the additional cost and time of painting, and the resulting paint fumes or residue. Three options for flooring are available: PVC, trowel-able epoxy and terrazzo. Each of these options are easy to install and ideal for high traffic or extended use areas.

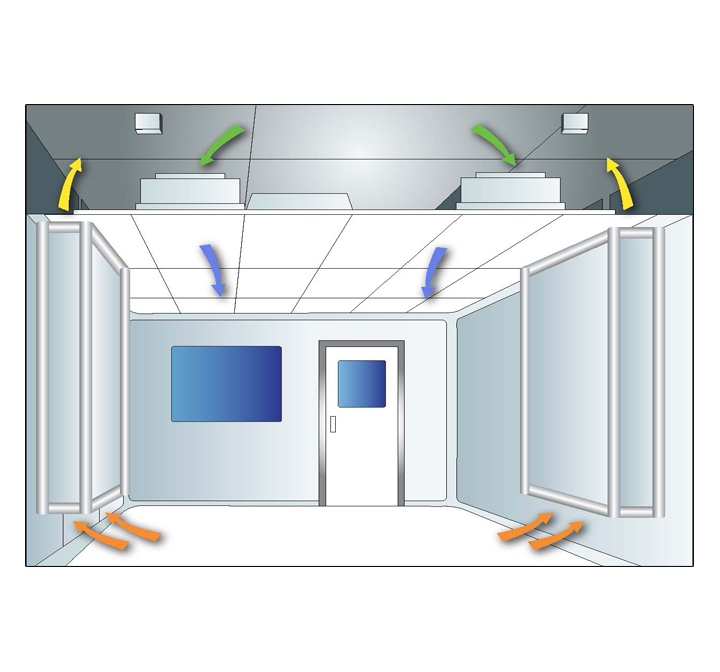

Whether the project calls for ISO 8, ISO 7, ISO 6, or ISO 5, we have the system to meet your needs. Each of our complete pharmaceutical grade cleanroom systems is designed with GEP, and all are compliant with FDA guidance and expectations for easily cleanable surfaces.

COST EFFECTIVE

In-shop pre-fabrication results in lower costs, higher productivity and more efficient use of labor, materials and tools than traditional on-site construction methods. Virtually no construction debris or residue. In-shop fabrication and on-site assembly by the same highly skilled technicians also assures quality and consistency throughout.

Our systems are also available in cost effective deployable models for quick transport and placement into other parts of the world. The deployable versions offer the same flexibility, quick turn around, and are also scalable like our standard modular clean room systems. The self-contained modules include HVAC systems, the same highly durable wall systems, utilities (as needed), and epoxy flooring. From a single 8 foot wide by a 53 foot long system, to several units interconnected and fully integrated complete facility for fill-finish, bio-processing, laboratory, pharmacy, or any need where a clean environment is required. Our systems can be ready for deployment in as little as 24 weeks after PO, and drawing approval.

SUPPORT

We offer our pre-engineering services to optimize our systems to meet your requirements thereby ensuring that your consideration is understood and incorporated into the design. As a turn-key solution we also offer HVAC systems with terminal HEPA filters, various lighting solutions, flooring options, and a host of amenities.